As a world-leading name in marine apparel our ethos has always been to think differently and push the boundaries of innovation. At the forefront of the industry, we redefine standards by embracing a unique approach. Rather than settling for conventional off the shelf branded fabrics in our range we make it our mission to develop our own fabrics, so we can ensure that they are truly fit for purpose and will withstand the rigors of the ocean. Whether it’s enhancing lightness, durability, or breathability, we engineer fabrics that surpass expectations. Our commitment to excellence is evident in comparative tests where our fabrics consistently outshine well-known brands.

Find out more about our exclusive fabric technologies XPLORE+® and XPLORE®.

Unyielding Waterproof Performance: XPLORE+® 3-Layer Fabric

This advanced material ensures a fully waterproof and breathable barrier, keeping you shielded from the harshest elements while allowing your body to breathe. Rigorously tested to a 35,000mm column of water on the Hydrostatic Head, this fabric not only meets but exceeds waterproof standards ensuring that you stay dry and comfortable regardless of the weather conditions you face. XPLORE+® doesn’t stop there; it goes through an exhaustive 8-hour Martindale test, a true testament to its robust nature. Subjected to continuous abrasion with grit paper, the fabric remains resolute, demonstrating an ability to withstand wear and tear that few others can match.

Your Gateway to Unmatched Protection: XPLORE® 2-Layer Fabric

XPLORE® boasts a robust 2-layer construction that forms an impenetrable barrier against the elements. Stay dry and comfortable in the face of rain, wind and unpredictable weather conditions. Rigorously tested to an impressive 30,000mm column of water on the Hydrostatic Head, this fabric not only meets but exceeds established waterproof benchmarks. Its steadfast resilience guarantees that you stay dry and comfortable, defying the challenges posed by unpredictable weather conditions. Undergoing a demanding 4-hour Martindale test which involves continuous abrasion with grit paper, putting the fabric’s tenacity to the ultimate test.

Products featuring XPLORE® and XPLORE+® Technology.

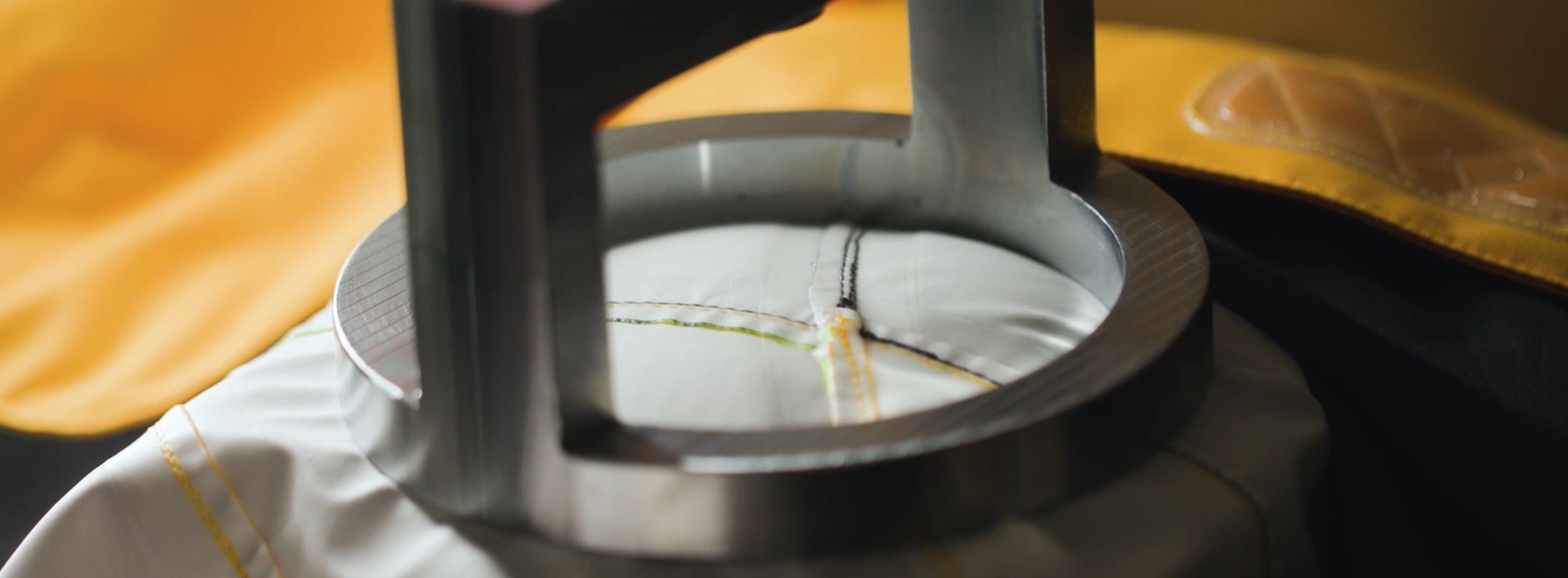

Hydrostatic Head Testing: Defying Water Penetration

Our commitment to excellence begins with Hydrostatic Head testing, a meticulous examination of how waterproof our fabrics are. This measurement, expressed in mm, represents how high a column of water would need to be before it penetrates fabric causing it to fail. At Gill, we believe in setting the bar higher when it comes to waterproof performance. While some international standards permit up to three water droplets to permeate before declaring a fabric non waterproof, at Gill we take a different approach – we stop at the first droplet. Our minimum testing threshold is 10,000mm, although the majority of our fabrics continue to perform well over an impressive 20,000mm, with our OS1 Ocean XPLORE+ fabric still waterproof over 30,000mm. Rest assured, our products are engineered to defy water penetration and provide unparalleled protection in the harshest conditions.

Breathability

Allowing a product to let perspiration escape is just as important as not allowing water in, particularly during active use. Of the three test methods available to show how many grams of water vapour are able to pass through a fabric, we use two, depending on the fabric type. To maximise the performance of your clothing system, we recommend using a base and mid-layer that encourage the process of moisture transportation away from the surface of the skin.

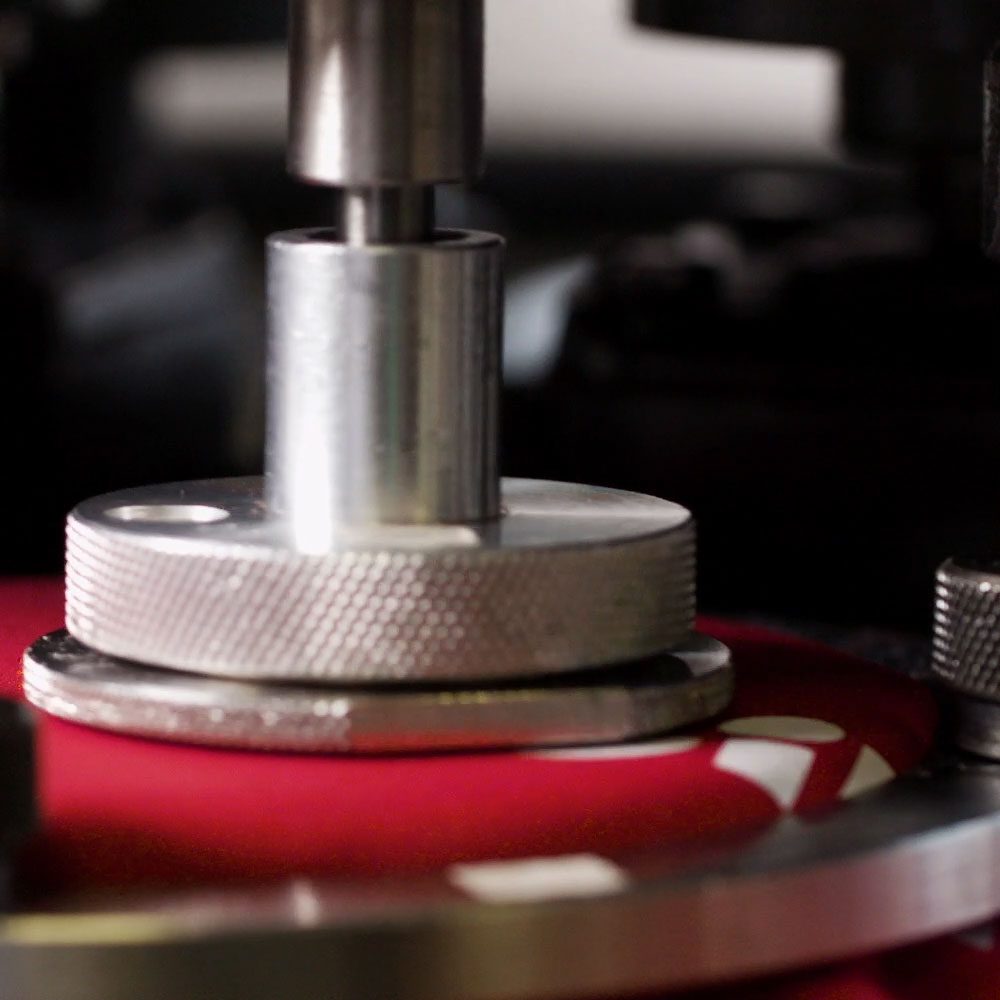

Martindale Testing: Unmatched Fabric Durability

To assess the durability of our fabrics, we employ the internationally recognised Martindale Test, also known as the ‘Rub Test’. Our version of this test yields true-to-life results by subjecting the fabric to continuous abrasion rather merely rubbing two cloth swatches together. Using a Martindale machine, a piece of fabric is placed between two discs, with one disc oscillating grit paper across the fabric until signs of distress appear. We hold our waterproof products to a minimum testing standard of 10,000 oscillations, which is three continuous hours of rigorous grit paper testing. Notably, our OS1 jacket undergoes an extensive 8-hour Martindale test, and where reinforcement fabrics are used such as the seat of the jacket or seat and knee area of the salopettes it is an impressive 33 hours of continuous abrasion testing ensuring unmatched durability for your adventures.